Dedicated Customer Teams & Agile Services

Download

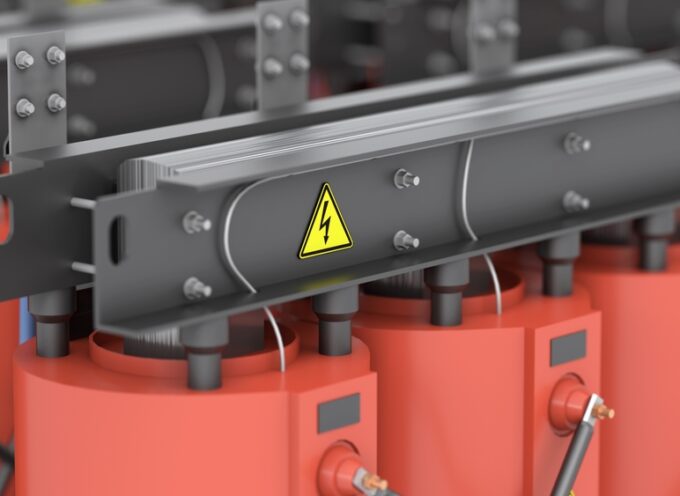

Distribution transformers are an essential part of the power distribution system, converting high-voltage electricity from the transmission grid to the lower voltage levels required for use in homes, businesses, and other establishments. These transformers are typically located at various points along the distribution system to ensure that the voltage is maintained at safe levels and that the electricity can be distributed efficiently.

Distribution transformers provided by Jaybee Industries are available in 3 Phase / Single Phase ranging from 5 KVA to 2500 KVA up to 66 KV class with off-load & on-load Tap changer with or without Automatic Voltage Regulator (AVR) & Remote Controlled Tap changing Panel. The cooling method used in these transformers can be either oil-immersed or dry-type. Oil-immersed transformers use oil as a cooling medium to dissipate heat generated during operation, while dry-type transformers use air as a cooling medium.

Overall, distribution transformers are an essential component of the power distribution system, ensuring that electricity is delivered safely and efficiently to homes and businesses. With proper design, maintenance, and operation, these transformers can provide reliable service for many years, helping to power the modern world.

Pre-commissioning tests

Based on IS 2026, Jaybee Industries transformers are subjected to several tests before commissioning with no compromise on raw material quality and ensuring the healthiness of the transformer prior to its energisation.

Lightning Impulse Voltage test

The purpose of the impulse voltage test is to detect whether the transformer insulation withstands the lightning overvoltage which may occur in service.

Air pressure test

The air pressure test is performed to determine the total pressure of all gases dissolved in oil and detect whether the transformer is completely sealed and the transformer body is strong enough to withstand the pressure.

Temperature rise tests

The temperature rise test of a transformer is important to determine whether the temperature limit of the winding and oil is as specified by the manufacturer.

Losses

We at Jaybee Industries, are manufacturing Transformers with Losses conforming to the Star Labelling Scheme as per the Bureau of Energy Efficiency ranging from Star 1 to Star 5 & as per Energy Efficiency Levels specified in the latest IS 1180 under time-to-time amendments ranging from EEL1 to EEL5. Our transformers bear the star label as shown in the figure.

Every Transformer dispatched carries our Routine Transformer Test Certificate which contains all the Technical Data such as Losses, Impedance, Ratio, Resistance, Insulation Level, Oil BDV, warranties etc.

We at Jaybee Industries are manufacturing transformers with the losses and impedance values as mandated for different Energy Efficiency Levels & kVAs.

Maximum Total Losses Upto 11 Kv Class Transformers (Clauses 6.8.1.1, 6.8.1.2, 6.8.1.3, 6.8.2 & 7.8.1.1)

Other Products

FAQ's

What is the range of Distribution transformers offered by Jaybee Industries?

Jaybee Industries, as a leading transformer manufacturers company, provides Distribution transformers in both 3-phase and Single-phase configurations, ranging from 5 KVA to 2500 KVA and designed for use in up to 66 KV class systems. These transformers come equipped with off-load & on-load Tap changer options, along with the choice of Automatic Voltage Regulator (AVR) and Remote Controlled Tap changing Panel.

Can you elaborate on the cooling methods available for Jaybee Industries’ Distribution transformers?

Our Distribution transformers, offered by leading transformer manufacturers, offer flexibility in cooling methods. You can choose between oil-immersed transformers, which use oil as a cooling medium and dry-type transformers, which utilise air as a cooling medium. This adaptability allows customers to select the most suitable cooling method based on their specific requirements and environmental considerations.

What pre-commissioning tests are conducted on Jaybee Industries’ transformers?

Jaybee Industries, as one of the leading transformer manufacturers in India, adheres to rigorous standards. Pre-commissioning tests, based on IS 2026, are integral to our quality assurance. These tests include Lightning Impulse Voltage tests, Air pressure tests and Temperature rise tests.

What makes Jaybee Industries’ Distribution transformers suitable for long-term and reliable service?

Being one of the leading distribution transformer manufacturers, we offer transformers that are designed, manufactured and maintained to ensure long-term reliability. With proper design, regular maintenance and efficient operation, these transformers can provide reliable service for many years, contributing to sustained and uninterrupted power supply to homes and businesses.

How does Jaybee Industries ensure energy efficiency and quality?

Jaybee Industries, as one of the leading transformer suppliers, aligns with the Bureau of Energy Efficiency’s Star Labelling Scheme, offering transformers with Losses conforming to Star 1 to Star 5 and Energy Efficiency Levels specified in IS 1180. Each transformer comes with a Routine Transformer Test Certificate, guaranteeing comprehensive technical data and quality assurance.

How do I choose a distribution transformer?

To choose a distribution transformer, consider factors like capacity, voltage rating, efficiency, and application requirements. Evaluate the load profile, environmental conditions, and reliability needs. Consult with experts and prioritize safety standards to ensure optimal performance and longevity for your specific electrical distribution system.

What are the types of distribution transformer?

The main types of distribution transformers include pole-mounted transformers, pad-mounted transformers, and underground vault transformers. Each type serves specific needs in electrical distribution, offering versatility and adaptability to various settings and applications within the power distribution network.

What is distribution transformer used for?

Distribution transformers are used to change electrical voltage levels for efficient power distribution. They step down high voltage from the power grid to lower levels suitable for homes, businesses, and industries, ensuring safe and reliable electricity supply in local distribution networks.

What is three phase distribution transformer?

A three-phase distribution transformer is a type of transformer designed to handle three-phase electrical power. It efficiently converts high-voltage three-phase electricity from the grid to lower-voltage three-phase levels for use in industrial, commercial, and residential applications, facilitating balanced power distribution.

What is the working principle of distribution transformer?

The distribution transformer operates on the principle of electromagnetic induction. When an alternating current flows through the primary coil, it induces a changing magnetic field, which, in turn, induces a voltage in the secondary coil, facilitating the transformation of voltage levels for power distribution.