Choosing the right transformer for the present infrastructure is usually grueling, with more than two options offered: high voltage dry type versus oil-filled transformers. Each of these transformers served different purposes, but since the requirements of smart buildings, hospitals, data centers, and metro networks have changed, so have the transformers.

At Jaybee Industries, we help our clients comprehend the solution that will be best suited for their operational goals, environment, and future scalability. Let’s explore both options and what often makes the high voltage dry type transformer favorite choice in many modern applications.

Understanding the Basics: Dry Type vs. Oil-Filled

Both oil-filled and dry type transformers are used to adjust voltage levels in electrical systems. The major difference is how the winding and core are cooled.

Oil-Filled Transformers

Oil-filled variants rely on insulating oil for cooling their internal components. The oil circulates through the windings and helps in dissipating heat. They are robust and generally preferred in outdoor or high-load industrial applications.

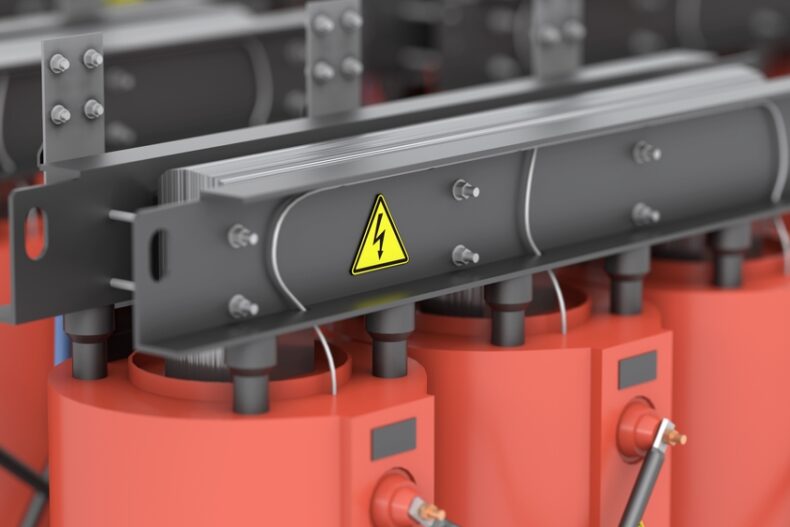

Dry Type Transformers

As the name goes, dry-type transformers use air, or sometimes epoxy resin, to insulate and cool the windings and core. A high-voltage dry-type transformer is hermetically sealed and requires no liquid insulation, the absence of which assures the cleaner operation, and safety considerations if either fire hazards or contamination could threaten an area.

Why Modern Infrastructure is Shifting to Dry-Type Transformers

As dry type transformer manufacturers, we’ve seen a significant shift in market demand toward dry-type units, especially in sensitive or indoor applications.

1. Safety

The dry-type transformers are non-flammable and are therefore suited for commercial buildings, shopping malls, metros, and healthcare facilities. There is no chance of leakage or explosion from oil, thus contributing to a great extent to operational safety.

2. Low Maintenance

To maintain performance and safety, they need periodic oil testing, filtration, and upkeep to avoid contamination. In contrast, dry-type transformers are almost maintenance-free. As leading dry type transformer manufacturers, we ensure our units are engineered for long-term performance with minimal intervention.

3. Space-Saving Installation

Dry-type transformers can be installed closer to the load center and even inside buildings, thanks to their compact and enclosed design. This flexibility is crucial for space-constrained areas like basements or multi-level commercial complexes.

4. Environmental Compliance

Modern infrastructure projects increasingly favor equipment that’s clean and environmentally compliant. Dry-type transformers align perfectly with these objectives since they don’t involve oil handling or the risk of ground contamination.

When Oil-Filled Transformers Still Make Sense

While dry-type units are gaining popularity, oil-filled transformers are still highly relevant in outdoor or high-load applications. Industrial plants, power generation stations, and large substations often prefer oil-filled types for their cost-efficiency and superior cooling in extreme environments.

However, these setups typically come with fire-suppression systems, larger footprints, and stricter safety compliance—all of which may not suit modern infrastructure formats like smart cities or urban real estate.

What Should You Choose?

Choosing between a high voltage dry type transformer and an oil-filled transformer depends on your project’s specific requirements. For indoor use, safety-critical environments, or where minimal maintenance is a priority, dry-type transformers are the go-to option.

At Jaybee Industries, we help clients across sectors make informed decisions. As one of India’s trusted dry type transformer manufacturers, we combine engineering precision with industry insights to recommend solutions that deliver consistent performance.

We also bring end-to-end expertise as a generator transformer manufacturer company, offering both standard and custom solutions designed to meet high-performance demands.

Whether you’re designing a new facility or upgrading legacy systems, our team can guide you toward the best-fit transformer technology, backed by quality, reliability, and future-ready support.

Let’s build smarter, safer, and more efficient power systems—together.

Also Read:-

The Advantages Of Partnering With Trusted Dry Type Transformers Manufacturers

Why Your Power Grid Needs A Future-Ready Transformer Supplier

More Useful Links:-

Large Power Transformer Manufacturers | Transformers For Hospitals | Furnace Transformer Manufacturers